China’s retired power batteries will reach 780,000 tons in 2025.

On June 22, a government regulation drafted by the National Energy Administration of China proposed that key breakthroughs in battery consistency management technology will be achieved. Before the performance monitoring and evaluation system is perfected, in principle, no new large-scale power battery cascade utilization energy storage project shall be built. Power battery cascade energy storage projects that have been completed and put into operation should regularly evaluate battery performance, strengthen monitoring, and strengthen supervision.

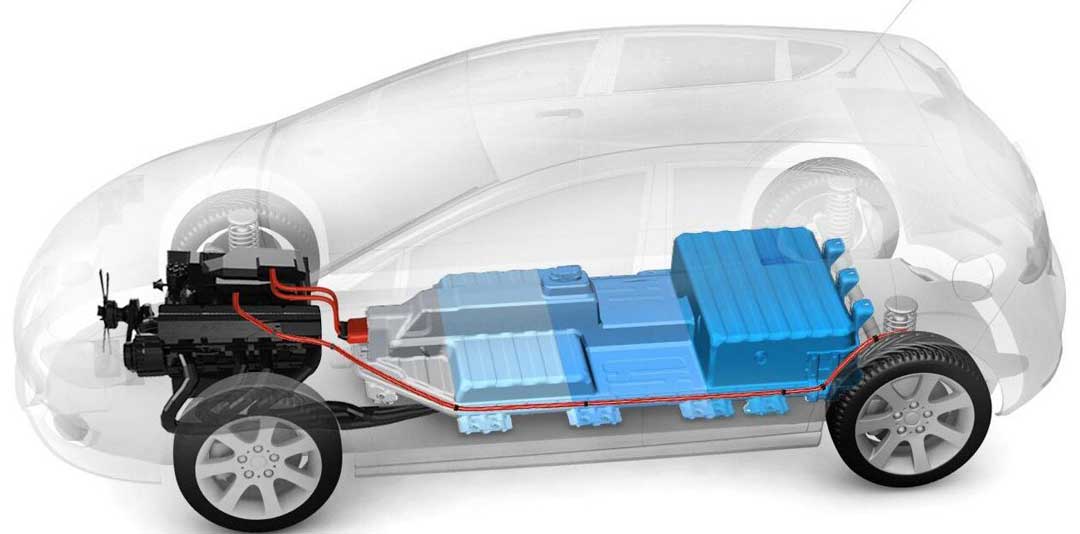

In fact, China’s first batch of new energy vehicle power batteries is already in an old state, and the entire industry is about to usher in the “retirement wave” of power batteries. According to data from the China Automotive Technology Research Center, in 2020, total power battery decommissioning will be about 200,000 tons, and by 2025, this number will rise to about 780,000 tons. The whereabouts of decommissioned batteries and how to handle them have become the industry’s concern & focus. This may be a new business opportunity for recycling batteries.

At present, there are two main ways to recycle power batteries in China: One is element recovery, which refers to the two main types of power batteries currently on the market, ternary lithium batteries and lithium iron phosphate batteries containing manganese and lithium, and more scarce heavy metal resources such as cobalt and nickel are extracted; the second is cascade utilization, that is, disassembling retired batteries into modules or batteries to form small batteries for low-speed electric vehicles, power tools, solar street lights, or the multiple battery packs are combined and used in photovoltaics, wind energy storage devices and other fields.

A professor from South China University of Technology in China put forward his point of view: The use of power batteries in cascades is very beneficial, but there are hidden dangers. The advantage is that it can extend the battery life cycle and ease the pressure of environmental pollution. At the same time, the batteries used in the cascade can also participate in the frequency and peak regulation of the power system to improve power quality. However, cascading utilization cannot fundamentally solve the problem of environmental pollution, and the abandonment and recycling of batteries will still come. In addition, there is a problem with fire safety hazards.

The “decommissioning tide” of power batteries in the Chinese market is approaching.

The ever increasing number of new energy vehicles has gradually brought the recycling of power batteries into people’s attention. Data show that as of the end of May this year, China’s new energy vehicle ownership is about 5.8 million, accounting for about 50% of the world’s total new energy vehicles. In 2020, China’s total power battery installed capacity is 63.6GWh, a cumulative increase of 2.3% year-on-year. The total installed capacity of global power batteries in electric vehicles is 137GWh, an increase of 17% year-on-year.

According to calculations by relevant agencies, starting from 2020, China will gradually enter the stage of large-scale decommissioning of power batteries. Among them, from 2020 to 2022, cumulative decommissioning of power batteries will reach 90.5GWh. By 2025, the tiered utilization and recycling market of power batteries is expected to reach 37 billion yuan.

The Chinese government has also issued a clear signal for the recycling path of power batteries. Prior to this, the Ministry of Industry and Information Technology has successively issued a number of management policies, all of which involve the management of echelon utilization. In October 2020, the Ministry issued the “Administrative Measures for the Echelon Utilization of Power Storage Battery for New Energy Vehicles (Draft for Solicitation of Comments)”, and the echelon utilization management has become a policy focus. Some pilot places further encourage and support the exploration of cascade utilization technologies and business models.

However, the industry has not yet reached a consensus as to whether the “road to decommissioning” of power batteries should be directly recycled or cascaded. The main controversy focused on safety, economy and reliability. For example, in terms of reliability, there are doubts about whether the battery can maintain a stable power supply capacity after retirement. Especially the ternary lithium battery, after reaching a certain number of charging and discharging, the attenuation is relatively serious.

Industrial chain coordination or cascade utilization of key

The problems faced by power battery cascade utilization are far more than this. It is understood that the power battery is usually customized according to the specific models of different car companies, and the structure, specifications and parameters of the power batteries of different car companies are quite different. Even for the same batch of power batteries of the same car company, the same model, the remaining capacity, voltage and internal resistance are not exactly the same at the time of retirement.

This also increases the difficulty and cost of using retired power batteries. After the battery is recycled, it needs to be tested first, then classified according to different sources, different specifications and different capacities, and finally reorganized and reused.

At present, the battery packs produced in China have different shapes and sizes, and many companies cannot automatically disassemble them. For battery packs, modules, and monomers with large disassembly and complex internal structures, if they are not handled properly, it is very likely to cause safety problems such as short circuits, liquid leakage, and even the risk of explosion. At present, there is still a lack of effective coordinated supervision in each link of power battery recycling, and the policy reward and punishment mechanism is still incomplete. However, the development of battery recycling companies is different, and it is difficult to carry out standardized management.

At the same time, there is currently a lack of effective detection methods for judging retired batteries.

“The first problem to be solved by cascade utilization is to accurately identify the recycled batteries and screen out the batteries that are ‘ill’. We have been doing research on the identification of batteries (SOH, SOC, SOP) to see what methods can be used to detect recycling as soon as possible. Once the battery cell or battery pack in question has been accurately determined which battery is in what state or the state of a certain PACK, there are ways to take corresponding measures for maintenance and management.” A Chinese expert put forward his point of view.

In addition, the current regulations on the recycling and circulation of power batteries are not yet complete, which cannot guarantee the smooth flow of recycling channels. The current situation is that car owners cannot find or are not sure whether the collection point is formal. Some power batteries collected from traditional 4S shops and other channels also flow into small workshops. Because small workshops under the banner of “high-priced recycling” and “home recycling”, compared with formal qualified recycling companies with a lower coverage of recycling points, the market share of small workshops can reach more than half, and even recycling companies have grown up and workshop that repurchase the battery.

An industry insider said that the most urgent problem to be solved in the industry is to break the inherent thinking and work together upstream and downstream. Vehicle companies really need to figure out a way to better cooperate with recycling and retired battery processing companies, including the required data, application scenarios, and the research of the entire system. The upstream and downstream must break the boundaries, instead of “he is him, I am I”. He believes that the cooperation process will generate more economic value and solve many safety problems.

For current echelon utilization of power batteries, some people in the industry suggest that the policies and regulations on the echelon utilization of power batteries should be further improved to promote the industry. Large-scale development brings economic advantages through scale. At the same time, it strengthens technology research and development, develops efficient and fast retired battery health status identification technology, and reduces retired battery diagnosis costs. As for the main engine factory, the battery design link must consider the future echelon utilization. Reserve space for echelon utilization in terms of module grouping method, internal and external structure, etc.

The above information comes from the National Business Daily (National Business Daily)